If your pathway, deck, or parking space needs urgent cleaning and you are stressed for time and energy, the best option available is to use a power washer. A well-designed pressure cleaning system can not only remove the accumulated dirt, grime, and muck, but also blast away stubborn and tough buildup to leave the surface clean and spotless.

Power washing equipment uses two significant variables - water flow rate and air pressure. Flow rate of water is measured in gallons per minute or GPM, whereas air pressure is represented as pounds per square inch or PSI. For any power washer, higher levels of pressure and water flow rate indicate the more power generated by the machine.

Why Power Washers are Considered Eco-Friendly?

Pressure washing is regarded as the fastest way to clean hard surfaces and remove unyielding deposits. It is also the most effortless way of cleaning hard surfaces, as in many cases, power washers obliterate the need to use scrubbers, dusters, and brushes. In most cases, operators can also avoid using harsh and dangerous chemicals. When combined with an eco-friendly and soap-free cleaning solution, these machines can deliver highly impressive cleaning results, faster than conventional cleaning machines and processes.

Professional Cleaners Prefer Power Washers for Commercial Cleaning

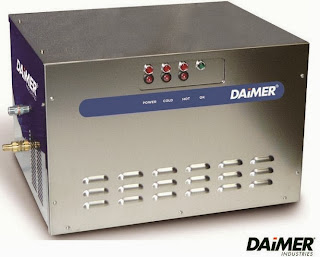

Power washers are highly recommended for commercial and industrial cleaning, as they are powerful cleaning machines with features that are tailor-made for comprehensive and effective cleaning of larger areas within the quickest possible time. The best pressure wash machines available can even remove grease from commercial floor and industry equipment, as they come with high temperature flow, which can be adjusted to meet the specific challenges and needs of a cleaning application.

Advanced power washers from top suppliers offer the convenience of hot water, cold water, and steam modes. They are powered by electricity and can be heated by propane, thus making the machines more versatile.

Power washing equipment uses two significant variables - water flow rate and air pressure. Flow rate of water is measured in gallons per minute or GPM, whereas air pressure is represented as pounds per square inch or PSI. For any power washer, higher levels of pressure and water flow rate indicate the more power generated by the machine.

Why Power Washers are Considered Eco-Friendly?

Pressure washing is regarded as the fastest way to clean hard surfaces and remove unyielding deposits. It is also the most effortless way of cleaning hard surfaces, as in many cases, power washers obliterate the need to use scrubbers, dusters, and brushes. In most cases, operators can also avoid using harsh and dangerous chemicals. When combined with an eco-friendly and soap-free cleaning solution, these machines can deliver highly impressive cleaning results, faster than conventional cleaning machines and processes.

Professional Cleaners Prefer Power Washers for Commercial Cleaning

Power washers are highly recommended for commercial and industrial cleaning, as they are powerful cleaning machines with features that are tailor-made for comprehensive and effective cleaning of larger areas within the quickest possible time. The best pressure wash machines available can even remove grease from commercial floor and industry equipment, as they come with high temperature flow, which can be adjusted to meet the specific challenges and needs of a cleaning application.

Advanced power washers from top suppliers offer the convenience of hot water, cold water, and steam modes. They are powered by electricity and can be heated by propane, thus making the machines more versatile.